Easy and Precise: Simplifying Fertilizer Spreading with Advanced Amazone System

Discover how Amazone’s smart systems are changing the way farmers in the United States spread fertilizer.

Find out how these high-tech tools installed in the Amazone ZA-TS simplify the spreading process and make it more accurate. READ MORE

It doesn’t get any simpler than this: No calibration

The ZA-TS’ weighing system makes spreading easier and more reliable.

It measures the materials accurately using two 200 Hz load cells, automatically comparing the applied rate to the set rate. If there are any differences, like when spreading mixed fertilizers, it adjusts the spreader automatically. Plus, it documents the applied rate for field-specific needs and allows for rate adjustments with a button press on the ISOBUS terminal.

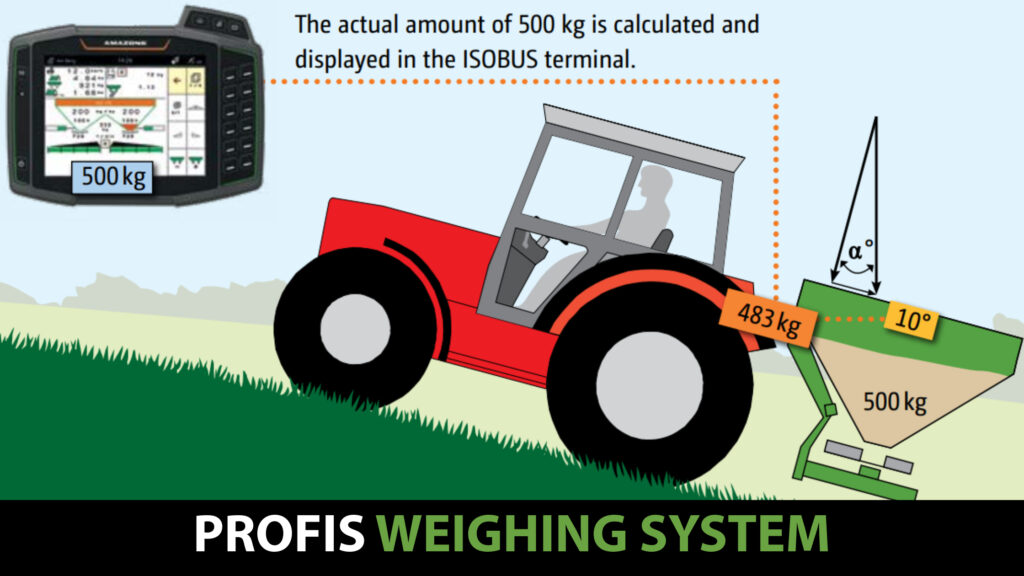

Tilt sensor designed for rough and uneven terrain

The Profis system in the Amazone ZA-TS incorporates a tilt sensor to actively compensate for the effects of gravity on hopper content measurement. This twin-axis tilt sensor evaluates both front-back and left-right tilt, effectively correcting any measurement discrepancies that may arise when navigating hills or slopes.

Thoroughly planned rate calibration: ProfisPro

Based on numerous spreading tests, the correlation between application rates and the torque generated at the spreading disc for various working widths has been determined.

In essence, lower application rates produce less torque on the disc than higher rates. FlowControl reliably monitors the torque on each spreading disc drive independently and promptly adjusts the position of the application rate shutters if there’s any deviation from the target rate.

Achieving the ideal spread rate right from the start

The combination of the smart weighing system and FlowControl allows the Amazone ZA-TS to adjust its application rate throughout the spreading process using torque.

The Profis weighing system checks the spread rate every 25 kg, enabling FlowControl to recalibrate continuously without stopping. With the ProfisPro intelligent weighing system, the spread rate is optimized right from the start of spreading.

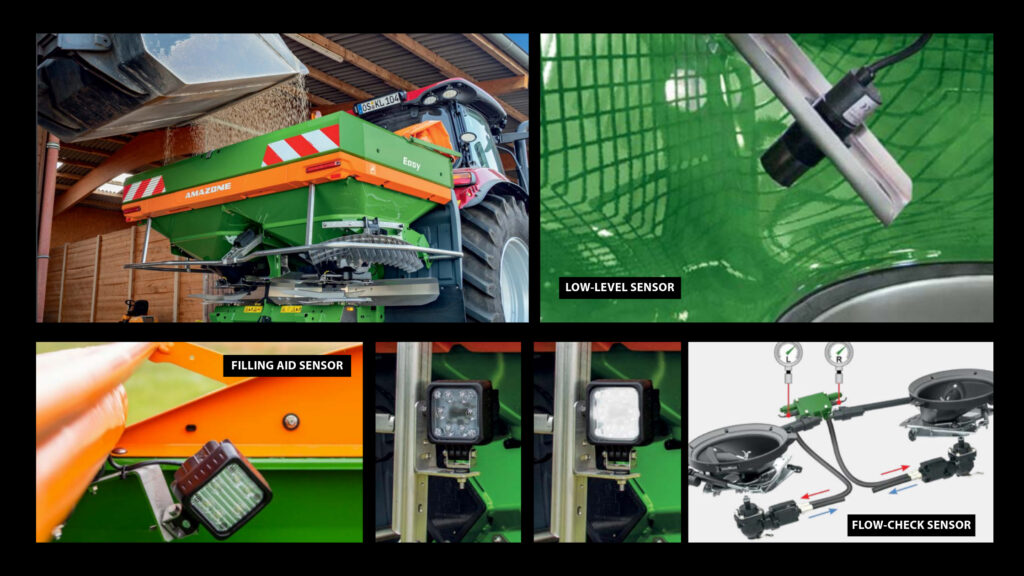

Monitoring the openings of the shutters

Amazone offers the FlowCheck monitoring device for the ZA-TS Hydro series as a cost-effective alternative to FlowControl.

While FlowControl can adjust the application rate independently on each side, FlowCheck only identifies blockages and when one of the two shutter openings is empty. In case of a blockage, both systems swiftly resolve it by opening and closing the shutter slide while reversing the agitator, ensuring reliable operation for farmers.

Very handy low-level sensors

When spreading on slopes or borders, it’s common for one hopper tip to empty faster than the other. To address this, Amazone offers low-level hopper sensors that allow for individual monitoring of each outlet aperture.

If one side empties prematurely, the relevant hopper tip is highlighted in red on the operator terminal, providing early warning to the driver. This ensures efficient spreading and helps prevent uneven distribution of materials.

Soft and gentle handling of fertilizer pellets

The agitator plays a key role in the fertilizer spreading process by actively moving the fertilizer towards the opening, ensuring a consistent application rate. Particularly at lower application rates, the star-shaped agitator at the bottom of the hopper works to break up any lumps that manage to pass through the sieve.

In the event of a foreign object reaching the hopper tip and causing excessive load on the agitator, the corresponding electric motor automatically reverses, while simultaneously opening the relevant shutter slide to clear any blockages autonomously. This ensures uninterrupted operation and prevents downtime due to blockages.

The precise coordination between the agitator and the shutter slide is especially noticeable on field edges and in wedge-shaped fields. When one metering aperture is fully closed, the agitator above it stops automatically, safeguarding the integrity of the fertilizer and preventing it from being ground up unnecessarily. This attention to detail ensures optimal performance and reliability in fertilizer spreading operations, even in challenging conditions.

Visit our website today to place your order or schedule a farm demo. Experience firsthand how Amazone’s innovative technology can optimize your fertilizer spreading operations and streamline your farming processes.