Explore RangeLine’s Complete Range of Planter Parts

Are you looking to upgrade your planter parts for better yield?

Look no further! From talc and graphite to closing wheels, twisters, seed discs, and parallel linkage components with bearings, we’ve got you covered.

READ MORE.

Seed Lubricants in your planter operations

These additives act as lubricants, creating a smooth and consistent flow of seeds through the planter.

Without them, seeds can clump together, leading to uneven spacing and depth control.

Talc & Graphite

By applying talc or graphite to your seeds, you ensure that each seed is treated individually, preventing them from sticking together and ensuring uniform distribution.

Moreover, talc and graphite reduce the friction between seeds and planter parts, allowing for easier movement and minimizing the chances of mechanical wear and tear.

DUST

This patented product has undergone rigorous testing at Kansas State University. DUST stands out for the absence of harmful chemicals like insecticides and carcinogens, ensuring the safety of both the farmers and the environment.

Moreover, it has been proven to minimize static and serves as a direct replacement for conventional options like Graphite or Talc.

In an independent study, DUST has demonstrated its exceptional performance by being up to 20 times less abrasive to seeds compared to Talc, thereby minimizing wear and tear during planting.

Benefits of Using High-Quality Closing Wheels

Closing wheels play a crucial role in ensuring proper seed-to-soil contact. They ensure that the seed is firmly in contact with the soil, allowing for the right amount of moisture and nutrients.

Without proper seed-to-soil contact, seeds may struggle to establish roots and may not germinate uniformly.

One of the key benefits of using high-quality closing wheels is their ability to create a firm seedbed. Firm soil promotes better moisture retention, as it reduces the chances of water evaporation.

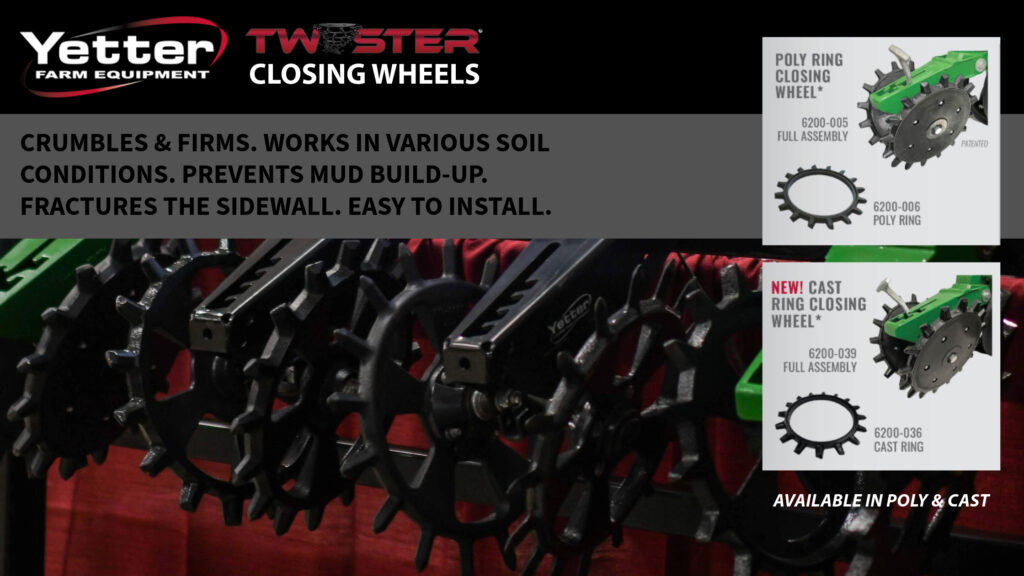

When choosing closing wheels, look for materials that are durable and resistant to wear like the Yetter Twister Closing Wheels.

Eliminating Guesswork with Set-N-Seed Planter Depth Calibrator

The Set-N-Seed is a revolutionary tool that gives you full control over the planting depth of your seeds.

With just a few simple steps, you can set the desired planting depth for your seeds. The device also comes with adjustable depth settings to accommodate different seed sizes, ensuring that each seed is planted at the optimal depth.

Proper seed depth is crucial for successful crop growth.

Planting seeds too shallow can limit their access to moisture and nutrients, causing weak plants. On the contrary, planting seeds too deep can delay emergence and reduce germination rates.

The Set-N-Seed planter depth calibrator eliminates these problems by allowing you to set the seed depth precisely. This guarantees that every seed is positioned at the ideal depth for best growth and yield.

Reliability of the Otico Farmflex Gauge Wheels

With top-notch engineering and quality components, the Otico FarmFlex Gauge Wheels seamlessly fit planters without any modifications needed, guaranteeing optimal performance without the hassle of replacing tires from time to time.

Thanks to its semi-hollow construction, the Otico Farmflex Gauge Wheels is proven to be puncture resistant regardless of the soil condition in which they operate.

These wheels also offer several advantages, including self-cleaning capabilities due to its unique rubber compositions and wheel configurations. Crafted from specialized rubber, these wheels offer the best quality for farmers in search of a reliable and a long-lasting replacement part.

For more information, click the following links:

Spoked Gauge Wheel Assemby: https://www.rangelinegroup.com/…/otico-farmflex-4-5-x…/

Regular Gauge Wheel Assembly: https://www.rangelinegroup.com/…/otico-farmflex-16-x-4…/

Choosing the Right Seed Disc for Optimal Planting

The first consideration when selecting a seed disc is the crop you’re planting. Different crops have different seed sizes and shapes, which require specific seed discs for optimal planting.

Another important factor to consider is the soil conditions in which you’ll be planting. Soil moisture, soil type, and residue cover can all impact the performance of the seed disc.

For example, in wet or sticky soil conditions, a seed disc with a more aggressive design may be necessary to prevent soil buildup and ensure proper seed placement.

Seed disc wear is another aspect to consider. Over time, seed discs can wear down, affecting their performance and the accuracy of seed placement. Regular inspection and maintenance of seed discs are essential to ensure optimal planting.

Replace worn-out discs promptly to maintain consistent seed spacing and depth control.

Exploring the Advantages of Parallel Linkage with Bearings

Parallel linkage components connect the row units to the planter frame, allowing for independent vertical movement and maintaining consistent planting depth across the entire planter.

The parallel linkage also absorbs the shocks and vibrations caused by uneven ground, providing a smoother planting operation and more accurate seed placement.

In the Exact Align Pro Parallel Linkage Arm design, various components such as the sealed ball bearings and bolts can be easily replaced during maintenance or repairs.

This rebuildable feature ensures that worn or damaged parts can be swapped out without having to replace the entire arm, saving time and costs while maximizing the arm’s lifespan and performance.

Maintaining and Replacing Planter Parts

Maintaining and replacing planter parts is essential for ensuring optimal performance and maximizing your planting efficiency. Regular maintenance and timely replacement of worn-out parts can prevent costly breakdowns and minimize the risk of yield loss.

Remember, proper maintenance and timely replacement of planter parts is essential for maximizing your planting efficiency and achieving optimal yields.