CRITICAL COMPONENTS: How Disc Blades Influence Your Crop Output

Disc blades are essential components in agricultural machinery, playing a critical role in soil preparation and crop cultivation.

Proper maintenance and timely replacement of these blades are vital to ensure optimal performance and longevity of your equipment. This blog will guide you through the various types of disc blades, their functions, and why it’s crucial to address maintenance and replacement needs promptly.

Types of disc blades

A. EDGE

The edge of a disc blade plays a crucial role in determining how efficiently the blade slices through soil and residue, affecting its overall performance in various soil conditions. The edge configuration influences the blade’s ability to cut, mix, and incorporate materials, enhancing its effectiveness in tillage operations.

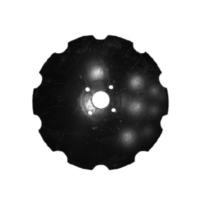

1. SMOOTH

A smooth edge allows for efficient soil penetration and minimal soil disturbance, making these blades ideal for light to moderate tillage.

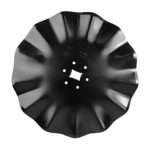

2. NOTCHED

Notched blades are particularly effective in handling heavy crop residue and compacted soil.

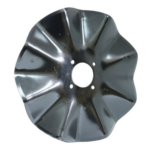

3. WAVY

Wavy blades are more aggressive, ensuring better disc penetration into the soil. They deliver impeccable cutting and mulch mixing, especially in extreme and damp conditions.

TIP: Their unique design also allows for self-cleaning.

Every type of disc blade has unique advantages tailored to various tasks. Farmers should choose the blade that best fits their needs, as each configuration brings its own set of benefits to the table.

B. CONCAVITY

Disc blade concavity refers to the curve depth of a disc blade, which influences its soil penetration, cutting efficiency, and the size of the furrow it creates.

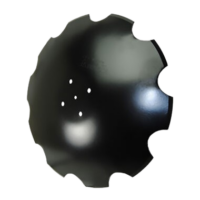

1. CONCAVE

Concave disc blades are curved to provide a scooping action that lifts and turns the soil. Concave blades generally wear faster on the edges but offer better soil penetration and mixing.

Flat blades wear more evenly and may last longer in abrasive conditions but offer less efficient soil handling.

2. Flat Back

Flat blades are ideal for routine tillage, seedbed preparation, and managing moderate residue levels.

CUSTOMIZABLE HOLES & PATTERNS

At RangeLine Group, we offer an extensive inventory of disc blades in sizes ranging from 16” to 36”, ensuring a diverse selection to meet your specific needs. Our cutting-edge CNC (Computer Numerical Control) plasma cutting table enables us to provide advanced and specialized customization options.

What truly sets us apart from our competitors is our ability to customize disc blade hole sizes and patterns on the spot. Through a simple three-step process, you can have your custom-cut blades delivered and ready to roll:

1. Choose from our extensive inventory of thousands of pilot disc blades.

2. Relay your specific hole size and pattern specifications to one of our sales representatives.

3. Relax as we swiftly deliver your custom blades, ensuring efficiency and convenience without delays.

As a leading supplier of farm equipment and replacement parts in North America, Rangeline Group takes pride in offering such specialized services, providing you with the perfect custom solution so that you can stay in the field longer & minimize any downtime.

How Proper Maintenance Increases Crop Yields

1. Optimal Soil Preparation: Better seed placement and improved soil-to-seed contact result in higher germination rates.

2. Enhanced Soil Health: Healthy soil structure supports root development, leading to stronger and more resilient plants.

3. Reduction of Soil Compaction

Worn-out blades can cause uneven soil tillage and compaction, which can hinder root growth and water infiltration. Early replacement of disc blades prevents these issues, ensuring that roots can grow deeper and access vital nutrients and moisture more effectively.

4. Efficient Weed Control

Reduced weed competition allows the crops to access more sunlight, nutrients, and water, contributing to higher yields.

5. Improved Water Management

Efficient water management ensures that crops receive the necessary moisture throughout their growth cycle, boosting yields.

Why You Should Replace Disc Blades Early Instead of Waiting for Wear

1. Enhanced Performance

Worn or damaged blades can reduce cutting ability, leading to poor soil preparation and increased fuel consumption.

2. Prolonged Equipment Life

Maintaining sharp and intact disc blades reduces the strain on your equipment, saving you money on costly repairs and replacements.

3. Improved Soil Health

Timely replacement prevents soil compaction and ensures that nutrients are evenly distributed throughout the field.

At RangeLine, we understand the importance of having high-quality disc blades readily available. That’s why we stock thousands of blades to meet your needs.

Our extensive inventory ensures that we can accommodate bulk orders and deliver on time, helping you maintain your equipment and keep your operations running smoothly. Don’t wait until it’s too late—ensure your disc blades are in top condition today.